Scorpion Sporsters...

1963-1965...

Photo Courtesy Ben Falconer...

Paul Wright (centre) looking at the ex Dave Lomas Scorpion trials bike now owned by Ben Falconer...

_______

Paul Wright was the designer and owner of the Scorpion brand.

Photo Credit Adam Taylor...2021...

One of the few Scrambles models that still exist.......

27/01/2021...

Another chapter to the Scorpion saga, because Adam Taylor recognised the photo above as his dad's machine. Malcolm Taylor for all pretence and purpose was the Scorpion factories "Works"scrambles rider, as can be seen in the photo's down the page.

He later bought the above bike from Bristol to get into Pre 65 Scrambling...

The Late (2018) Malcolm Taylor, aboard the Scorpion he bought to get into Pre 65 Scrambling.

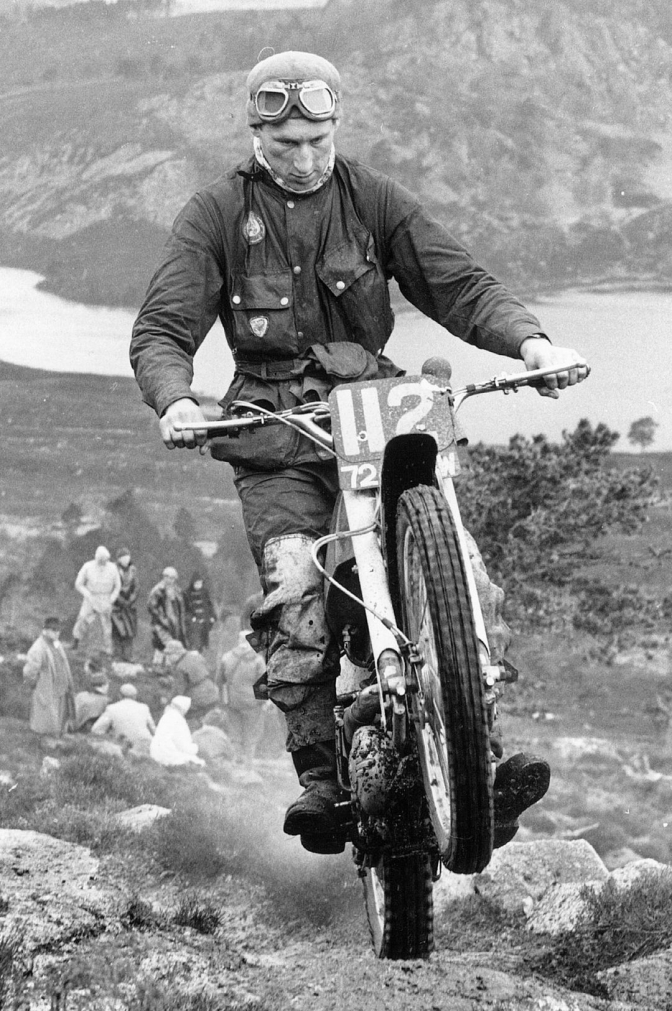

1963 and Malcolm Taylor presses on, aboard the "Works" Scorpion scrambles bike...

More from Adam Taylor down the page...

_______

Motorcycle article 7th March 1963

This week marks the arrival-of another manufacturer of sporting motorcycles.

The machine is the Scorpion, designed and produced by 26 year old Paul Wright at Bishops Stortford.

Paul has practical experience as a rider in trials, scrambles and grass track, meetings.

And he is the designer for one of the country's leading sport-car firms.

This combination stood him in good stead when he set out to design a trials and scrambles bike just over a year ago, that met his ideals, and ideas.

The aim has been to produce a model that would except a number of power units that would suit the choice of the individual.

The spine type frame fabricated from sheet steel is roughly L shaped ,its 5 inch deep member tapering to two inches wide at the front, which carries the steering head to four inches at the back.

Welded to the rear is a vertical member providing a location for the pivoted rear fork spindle.

Again the rear fork and two arms which extend rearward from the angle of the main frame to locate the rear suspension units, are sheet steel fabrications.

A bolt-on engine cradle that can be made to take various units is of square steel RHS (Resistance Welded Hollow Section) tubing.

It is attached just below the steering head and curves rearward to meet the lower extremity of the vertical member.

Front forks are of leading link-pattern with a bracing loop.

This pair just came to light in Australia in November 2022..

Armstrong links and front and rear suspension units are employed.

The twenty one inch front and eighteen inch rear wheels have MotoLoy full width hubs with six inch diameter brakes.

Rubber Cush drive is fitted to the rear hub.

Mudguards are Glass-fibre, the rear one being quickly detachable and incorporating a seat and rear number plate.

Removal gives access to a tool box in the vertical frame member underneath.

Glass-fibre is used again for the fuel tank which is available in either one or two gallon capacity.

Weight of the machine is 210 lbs with a Villiers Power unit fitted.

Other details include Amal alloy brake and clutch levers, and adjustable rear footrests and brake lever.

It is intended to market the Scorpion in kit form,

Cost will be about £110 without an engine,

Villiers 197cc, or 246 cc with Marcelle or Parkinson conversion will be available.

Address of Scorpion Motorcycle Development: is

40 Rochford Road, Bishops Stortford, Hertfordshire.

Peter Fraser 7th March 1963...

Photo Credit Ray Fazey. 2014...

This is friend Mick Salt's BSA C15 engined Scorpion machine, now in the process of getting rebuilt to put onto the road to be ridden, for the fun, of riding a Classic 1963 very rare sports motorcycle.

This must be the original Mock up Scorpion trials machine,

The production Glass-fibre tank and seat-mudguard unit, and front mudguard, were made by Chris Butler. (BML)...

_______

Riding in the 1965 SSDT below. It is said that Chris Cullen kept a welder very busy over the week end of the trial, but that was one way to test the machine, in the longest toughest observed trial in the world at that time.

Photo Credit Deryk Wylde, Off Road Review-e.

Chris Cullen a rider with a great deal of skill Gave the Scorpion the best chance to be a successfull brand of competition machine...

Photo Courtesy Deryk Wylde Offroad Archives...

And this showing in the 1965 Scottish proved the Scorpion to be a very capable ride...

_______

This next photo down of Dave Lomas who was one of the few to actually have owned a production Scorpion trials machine, converted his frame to hold the fuel in the top frame member, a very sensible idea, and one that would have probably been put into practice by the factory if the production run in their new unit at Whitfield near Brackley in Northhamptonshire, had been longer.

The run of production unfortunately was only two years and the factory closed in 1965...

What a shame, probably lack of funding and the running down of the motorcycle industry in this country did not help. But I think the concept that I still feel is brilliant was way ahead of its time?

But was it... Don't forget the Japanese motorcycle industry were already making pressed steel frames for their machines.

But Paul Wright's thinking of keeping it simple, meant that the frame unit could be built in a small workshop with nothing more complicated than a steel sheet folding machine, and someone that could weld steel seams.

Before the appearance of a mig welder, don't forget, these seams were probably done with a Oxy-Acetaline gas torch.

(I will let you know when I have looked closely at one of the welds,)

The first frames were actually built in a small workshop in North London by two sidecar road racing engineers, Bob Robinson, and Ted Young.

So that proved a point, yes anyone with these facilities, could still make a Scorpion type trials frame, using this very same method today...

_______

Again photo Courtesy ORR-e...

This machine that Dave Lomas is riding was later passed on to Ben Falconer.

Who then rode the machine a couple of years ago (2012) in the Scottish Pre 65 Two Day trial.

~~~~~~~

You can clearly see below, the space for the tool box in the vertical seat box in this scanned shot.

And just look at the footrests, and the position of the handlebars, how times have changed.

This seat pillar was used for the air-cleaner unit on the Scorpion Scrambles version, as can be seen in the heading photo of Malcolm Taylors machine...

I hope to continue on this page when I get new material. Later...

~~~~~~~

Below

This is the race version that I saw at the Motorcycle Show in London...

We all thought there were no engine innards.

It was a very pretty machine even in its mock up state.

Banbury Motorcycle journalist Bruce Cox allegedly had arranged to have Banbury GP road racer Rodney Gould the ride on the bike once it was finished, but I don't think Rod ever threw his leg over the machine, but

~~~~~~~

It as been said that the machine did complete a test day at the Silverstone circuit, with some of the Scorpion trials riders present. But who actually did the Testing, Mr Gould, we may find out one day...I hope.

~~~~~~~~~~~~~~

These next two Photo's are Ben Falconer's machine, (ex Dave Lomas)

He rode this in the Scottish Pre 65 Two day trial, in 2012.

And has an entry again this year 2016...

We will see how he gets on.

Photo's are Courtesy Ben Falconer...

More later... Hope to get Ben's Story, HERE...

And perhaps Dave's too...

_______

Photo Courtesy OffRoad Archives.

Just got these two photos of Ben Falconer competing in the 2016 Scottish Pre65 trial...04/12/2024...

_______

Photo Courtesy Offroad Archives.. Deryk Wylde...

Ben consentrating hard on the little Scorpion...

You can see by December 1963 the address is Scorpion Motorcycles,

Silverstone Works,

Whitfield,

Brackley,

Northamptonshire.

:There is a Spine type frame built out of 16 gauge sheet steel;

:Trials TYPE 2 is powered by a Villiers 32A unit;

:On The Trials TYPE 2 "Replica", the standard cylinder assembly is replaced by the Parkinson alloy Conversion;

~~~~~~~

08/03/2017.

Hi Charlie,

I've enjoyed your BSA Otter site for several years, but until this morning

I had not noticed the page on the Scorpion frames. The article and

photos of the scrambler and unit single BSA are new to me and much

appreciated! I already had some of the SSDT photos from Trials

Central.

I can see that the above-engine spine and seat boxes/rails are welded

to the front and back of the vertical box. How are the main boxes

formed?

Did they do two "C" halves and then weld those together with

two central seams on opposite sides, fold it all up from one piece and

have one weld seam in the middle of a face or at a corner, fold a

large "U" shape and then add a plate to close it off with two edge

seams on either side of that or ?

Do you know if there were any

bulkheads in the main boxes as seen on some riveted-up aluminum RR

monocoque frames?

I had a vintage scrambles project based on a Motobi with a box section

frame and you can see some photos of the Motobi frame here:

http://www.eurospares.com/motobi2.htm

Cheers,

Michael Moore...

Charlie,> Michael, I will get in touch with the owner of the BSA engined Scorpion, and go and take some photos, because I also would like to know how the frames were actually folded and welded. A very interesting machine and it is a shame the a draw to the film industry? actually was more than likely why production ceased? Or did it actually ever really start?

Get back to you Michael.

27/01/2021...

More from Adam Taylor about is dad Malcolm, who rode for Scorpion...

1963-4...

This photo looks to be probably one of the first times out on the Scorpion Scrambles machine, ridden by Malcolm Taylor, and it did win its class first time out at Stoke Lyne....by Bicester...

From Motorcycle-Mechanics Dec 1963...

Full portrait photograph of a man on a mission...

Malcolm Taylor Scorpion...

Malcolm's friend, Mike Meadows, did a bit of research on the Scorpion results, and scrambles that Malcolm raced in...

Number 13 unlucky for some, and it seems like it was for Scorpion Motorcycles...

Again we have found out more than we could have hoped for when I started this page about Scorpion Sportsters.

And I know Paul Wright has also read the page.. Once again thank you to Adam Taylor for this superb update...

21/12/2019...

The Scorpion BSA C15...

You Can see in this shot of the bike, the nicely bent engine under-run frame, this was bent especially for the the job, of holding the BSA C15 engine in the correct position in the Scorpion frame...

~~~~~~~

Well Just when you thought you had a story right in your head, and there was no evidence to prove different, saying that the Scorpion BSA C15 must have been built in the factory as it was that good a job.....

An email changed all that overnight...

For I now know who built the bike up and have the photo's to prove it..

So here is the story by "A Local Bike Enthusiast"....as he likes to be known ...

The Scorpion. BSA...

Here are the additional notes regarding the build, of the BSA C15 engine’d Scorpion, in no particular order.

The Engine . Surplus metal was carefully removed from the rockers and burrs on the tips of the thrust washers were dressed, in the engine build. Also a pair of match weighted push-rods were fitted along with the hot Sports cam. Charlie~Oo> Just looking at the big bore carb and smooth inlet tract, I could see this motor had been breathed on...

After reading the text on this page the builder of the bike had his memory jogged for a few more details, so I have just placed them on how he sent them to me..

This is how the stories always unfold when your memory hopefully comes back after a fifty year period not even thinking about the build... Great stuff again..

~~~~~~~

The project began with a Scorpion rolling chassis followed by an engine and various parts from a defunct C15, all obtained from Mr Churchill of Silverstone. Northhants, Subsequent internal engine mods included a 'hot' camshaft, lightened and matched push rods, polished ports, etc. Externally the raised cast ribs on the timing cover were removed and a hole was bored for easy access to the clutch cable. The cover was polished and the hole blanked off using a rubber plug from a C15 petrol tank mount. The exhaust pipe was another BSA C15 item cut and welded to the required shape. It remained unfinished before the bike was sold. The original rear wheel that came with the rolling chassis was in poor condition and so a conveniently available item from a Norton International (being broken for spares by a local enthusiast) was shoe-horned into the swinging arm. The single front down tube of the frame continued beneath the original engine but had to be truncated to accomodate the BSA C15 unit. It was replaced by two curved members fashioned from steel strip to match cardboard templates by an amateur blacksmith from Wolverton. The frame was finished in yellow hot spray paint sourced from R J Flemmings, a business that manufactured agricultural machinery and sold and repaired cars and motorcycles in Stony Stratford at the time.

~~~~~~~

The handlebars on the bike as pictured on your web site are not those that came with the rolling chassis. The original bars were high-rise and feature in the two photo's below. The rolling chassis when I got it had scrambles tyres fitted. The original rear shocks had exposed springs and resembled those presently shown on your web site, but as you will see from my photo's fully enclosed units were incorporated during the build because the modified bike was intended for road use. The originals were 'shot' in any case because the bike had seen some rough use, probably as a scrambles bike, presumably in competition. Charlie ~Oo> (As most of the parts for the rebuild came from the Churchill’s At Silverstone the bike could easily have been scrambled by the late Wilf Churchill Jnr.)

A speedometer that I added, with a drive taken from the Norton rear wheel, has been removed since the bike was sold and it appears that both road tyres that were on it at the time have been replaced.

There was no chain guard on the rolling chassis and I did not fit one. The chain guide attached to the swinging arm was in poor condition and was replaced.

I had planned to modify the 'footrest bar' to accommodate folding rests and give ample clearance for a kick starter but the bike was sold prior to completion to make way for a BSA DBD34 Gold Star... with all the trimmings!

I have done my best to relate everything correctly. An intervening period of almost 50 years is a long time. One other snippet of information while I think of it - the excellent bronze welding associated with the modifications to the bike was done by the late Charlie Johnson of Johnson and Ibel, a small metalwork and paint spray business that was based in Vicarage Road, Stony Stratford. You may have known Charlie if you lived locally. He was a very skilled craftsman. Almost all of the custom made parts are down to me, as was the concept and the work on the build itself. Therefore I accept full responsibility for mutilating a piece of motorcycling history! Charlie~Oo> No you actually added to it, as without this bike turning up the story might never have been told…So thank you...

If there are any gaps in the story please do not hesitate to contact me. It has been a pleasure to assist, and a trip down memory lane for me.

The following are two photos of the bike taken just before I sold it to some lads from Pottersbury. (Churchill Motorcycles are based here... Charlie.)? If I recall correctly. They would be about Mick Salt's age now I would guess, and my age too as it happens. If Mick lives locally (i.e. in the Milton Keynes area) it would be a treat to see the bike again at some future date, with his agreement obviously.

Charlie~Oo> Mick lives in an Oxfordshire Village, but we will see what we can arrange...

"A local bike enthusiast". Thank you.

Best regards, B...

The Scorpion BSA when first rebuilt with the BSA Engine.

What a good job it was... It fooled me...

I love these stories that reveal the truth about a bike, or how they came into being... Great Stuff...

Taking a look at this Photo of the bike, and the first colour photo at the upper part of the page the Ray Fazey 2014 shot... of the bike displayed at the Wigginton Oxfordshire Village fete... You will see that it looks like the bike has the same tyres fitted?

This Scorpion BSA could have remained in its unfinished state for the past fifty years and was it ever run, we don't know... The story just gets more interesting...

~~~~~~~

You Can see here the modified timing case...

This shot clearly shows the steel engine under-run rails...

~~~~~~~

More on this later...

Bike below as I last photographed it in March 2017..."Otterman"

And what I thought at that time the bike to be a Scorpion Factory build, and built for a long distance trial...

Three Day trials tank? Or even six...It was large even for a scrambles bike.

A good shot of the Scorpion frame, and how well the BSA C15 engine suits it.

~~~~~~~

You can clearly see the make up of the three boxes frame members here.

I Still think the suspension out-riggers are very wide at 10" normal practice seems to be 9" at the most. What does deceive though is the fact that the top suspension mounts are actually inside the out-riggers.

And the way the boxes are bronze welded together and not Mig'ed, it was the period before Mig welders were readily available.

and Tig or Argon-Arc was still very much in its infancy.

~~~~~~~

But we now know from the story of the bike above that the bronze welding on this machine was actually repair welding carried out by the late Charlie Johnson...

You Can see that this BSA C15 engine was fitted in the factory at the time for the fact that the head steady was made as part of the fixtures.......

~Oo>Fooled me it was that good a job...

And again the front engine mounting was done as the frame was made, and spacers machined for the job.

The Scorpion tank badges were made in the jewellery quarter somewhere by the look of them. No expense spared there.

The machine seems to be long and low despite the box section, but we know the measurements add up.

Today longer suspension would be the norm at the back end, and longer forks on the front.

But in 1964 the rule was that a line draw through the centre of the wheel spindles also passed through the centre of the engine crankshaft.

Now take a look at Ben's Blue bike above.

~~~~~~~

~~~~~~~

Photo's Courtesy "Otterman"©

Owner Mick Salt with his proud Scorpion possession.

Such a shame the Scorpion works did not last longer because this engine suits the bike, but unfortunately it was at-the start of the British Motorcycle Industry meltdown.

~~~~~~~

This is Mick Salts rather special Scorpion Machine.

~~~~~~~

After taking the photo's and closely inspecting the machine it is conclusive that this machine was built by the Scorpion factory in the format that it is still in today.

And the only conclusion that I can come up with, is that it was built to be a Welsh three Day trial or ISDT machine.

This would account for the British Hub front brake being fitted, the same as used on the Cotton Telstar racer, and the rear quickly detachable Norton hub fitted, the fitments for the sprocket guide etc, where defiantly Factory fitments.

And there are holes on the Butler back mudguard seat unit for attachments of numberplate and lights.

The late 1959 BSA C15 engine unit fitted looks to be in unused condition, even with the small head fin next to the spark plug is still there un-heard of.

And the inlet manifold is

fitted with a 376 large bore Amal Monoblock Carb, again makes me wonder what is inside the engine.

This may become a story on its own if a very prominent BSA personalty gets to take a look inside. Rupert Ratio no less.

~~~~~~~

The frame number 00003/4 would suggest to me that the machine had been built in 1963? hence the "3" and the 4 standing for Four-stroke, Mick suggests "4" stands for scramble bike?

Or Would the "3"or "4" suggest the number of machines built?

~~~~~~~

Photos Courtesy "Otterman"©

~~~~~~~

Frame measurements for you, and me, Michael Moore.

The frame construction is of considerable interest.

It is made up of basically two folded tube box sections, these where finished with a two flange seam and then gas welded without using a rod and just melting the flange steel together,

(This was one of my first tasks at college to make a box in this manner, I chose to go further and made it into an oil-take to the amusement of the lecturer at the time.)

Anyway these two box sections, the top 18" long, 4"wide at the rear, and 2" at the front where it meets with the 6 1/4" long steering head tube.

This joint was Bronze welded, to the steering head.

and the section is 4 1/2" -5"deep.

~~~~~~~

And the second 18" long tapering seat/swinging-arm box section, this is 4" wide by 4 3/4" long, Back to front at the top, square.

tapering again to 2" at the bottom engine-footrest mounts.

~~~~~~~

What surprised me is that the suspension top mount measure 10"across.

~~~~~~~

And these again are made into a fabricated unit with 16 gauge folded flat steel and then welded to a triangle shaped reinforcing wedge before again being Bronze welded as a unit to the seat box.

The Swinging arm is 18" long from pivot, to wheel-spindle.

~~~

And 15 3/4" from the front brace tube.

~~~~~~~

Everything, brackets, Etc. are Bronze welded, and only the box seams are run along with a gas torch, and I must say the guy that did these could use that torch.

~~~~~~~~~~~~~~~

Steel used for the frame was 18-16 gauge mild steel for the main two boxes.

And 16 gauge mild steel for the top suspension mount outriggers.

Steering head angle was 62 degrees on the trials bike, 64 on the Scrambler.

The weight of the frame was said to be 11 Ib, but I think this figure optimistic...

Wheelbase 51 1/2 -52 inches.

Front engine tube 16 gauge 1 1/8 ERW tubing.

Swinging arm 1 1/2" x 3/4" 16 gauge RHS,

1,1/4" 16 gauge Swinging arm stabiliser tube...........

~~~

Data if you are thinking of building a frame like we are.

~~~~~~~

Bonhams 2009.

Frame no. S0008/4

Engine no. 0005D 24176

~~~~~~~

The story on Mick's machine will now run as it is planed to press on with the rebuild as soon as possible.

Feb 2018...

~~~~~~~

You know, We have been in touch with Paul Wright's daughter Susan, and if we possibly can, we will try and arrange for Paul to visit Mick and take a look at the machine, and he may give us the missing information.

~~~~~~~

Susan's >Mail

You wondered on the website why Scorpion only lasted two years?

It was because the guy who was helping to fund the company pulled out unexpectedly, leaving Dad and his business partner in tremendous difficulty.

They had to break into the workshop to rescue their own tools! My parents ended up emigrating to Africa after that, as Dad had a job with Lotus cars.

He also worked as a designer for Aston Martin, contributing chassis design (I think) for the DB5.

Anyway, lovely to read your website,

Best wishes,

Susan...

2017.

I thought you might like to know that my dad is still alive and we both looked at your website together.

He was really chuffed to read about his bikes and see your images.

Dad bought his last motorbike (a Harley) at the age of 70 and gave up riding 5 years ago.

Anyway, we are so thrilled to see the images of the bike,

Best wishes,

Susan...

More later as always.

("Otterman pic)

Over The Rainbow?

Watch this space.

~~~~~~~

A Lot More to come.24,10...

Updat2025...06...